Products

-

Rubber Bellow Seal

-

Single Spring Seal

-

Multi Spring Seal

-

High Pressure Seal

-

Teflon Bellow Seal

-

Metal Bellow Seal

-

Dry Running Seal

-

Split Seal

-

Wet Running Seal

-

Double Unbalanced Seal

-

Industrial Seal

-

Bearing Isolator Labyrinth Seal

-

Chemical Process Pumps

C-23 Shukla Industrial Estate, Singh Compound,

S.V. Road,

Jogeshwari (W), Mumbai-400102,

Maharashtra, India.

Opp. A.P. Market, Amber Colony,

Udhana, Surat, Gujarat, India.

328, 3rd Floor,

Sayaji Gang, Phoenix Complex,

Baroda – 390005, Gujarat, India.

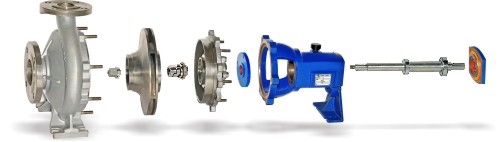

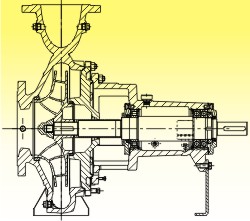

Quba Chemical Process Pumps are designed with few components to make them more robust and easy to service. The back pull-out unit is always a one-piece component and the cover on all the sizes is equipped with forcing screws for dismantling. These two features make the Quba Chemical Process Pumps easy to service. The conical seal chamber is enlarged to reduce wear when handling aggressive fluid and it improves the venting of fluids that contain gas.

- Hydraulic characteristics optimized for excellent efficiency and NPSH, ensuring energy-efficient and environmentally friendly use of resources.

- Lower investment costs as duty points required can be achieved with smaller pump size.

- Lower operating costs due to reduced energy consumption, optimized spare parts concept and hard-wearing, service-friendly design.

- Optimized hydraulic systems for improved handling of gas containing liquids and solid laden fluids.

- Single or double volute, depending on the pump size

- Radially split volute casing

- Volute casing with Integrally cast pump feet

- Replaceable casing wear rings (as required)

Closed radial impeller with multiple curved vanes

Medium –duty

Radial bearing : Cylindrical roller bearing. Fixed bearing: Paired angular contact ball bearings / double-row angular contact ball bearing.

Economy

Floating bearing assembly: deep-groove ball bearings

The calculated minimum bearing life is:

- 17,500 h for economy bearing assemblies

- 25,000 h for medium-duty bearing assemblies or 40,000 h for operation between 0.7-1.1

- Gland Packing

- Commercial single and double mechanical seals

- Commercial cartridge seals

- Shaft fitted with a replaceable shaft protecting sleeve in the shaft seal area.

- Optimized single-piece bearing bracket

- Excellent thrust balancing

- Heating/cooling jacket for the most demanding fluids

- Fully confined casing gasket and metal-to-metal contact

- Easy-to-service mechanical seals

- Improved pressure/temperature range in our stainless steel models

- Volute casing pump

- Horizontal installation

- Back pull-out design

- Single-stage

- Conforms to the technical requirements of ISO 5199

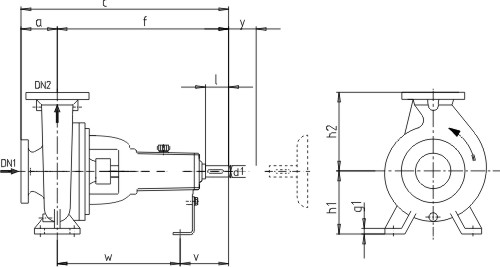

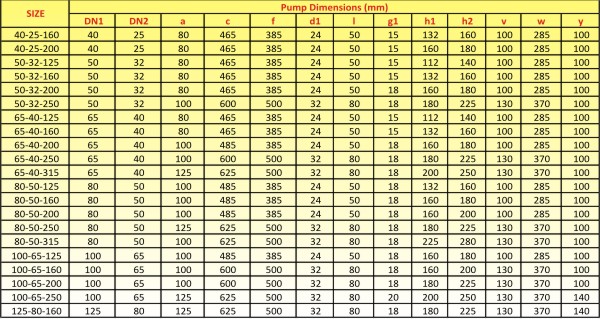

- Dimensions and ratings Conforms to EN 22858/ISO 2858

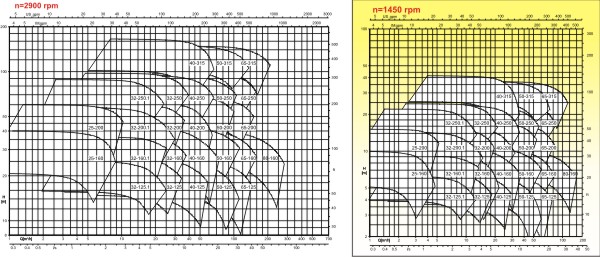

Capacity |

: Up To 160 M3/Hr. |

TDH H |

: Up To 140 Mtr. |

Speed –N |

: 1440/2880 rpm at 50Hz |

Temperature |

: -40 to +335 Deg C |

Pressure |

: Up to 25 bar |

SS304 |

CAST IRON |

SS304L |

BRONZE |

SS316 |

CARBON STEEL (WCB) |

SS316L |

ALLOY 20, HASTALLOY C/B |

Pumping Liquid |

|

Pumping Temp. |

(Deg C) |

Suction Pressure |

(Kg/Cm2.) |

Flow |

(m3/hr) |

Head |

(m) |

Chemical Steel Industries |

Pharmaceutics |